Where are all the NIMBY s???

Where are all the NIMBY s???

My usual footing/cribbing crew arrived at the new job site along with the structural engineer. The homogenous sandy condition of the excavation has been very interesting. This part of Richmond must have been an area of heavy deposition during the ice age melt down to have left behind this much sediment. Soil bearing of course is more of a concern on these sandy soils. End result is just add some width and rebar to the footing and carry on.

This footing would be a nice beach. the soft conditions make for a much easier place to work in.

The 2111 house found itself in the back of the dump truck early this morning. With the house removed we can start the real work.

Thanks ‘troublemaker Neighbour’ who already accused us of operating without a permit and without removal of the asbestos. He called the city after raising a large ruckus and eventually the city told him to go away. Its nice when the city staff get involved and take my side in a dispute before it can escalate. These projects cost a lot of money to run by the day and we don’t need work stoppages, particularly when we’ve done the right thing and fulfilled all our commitments.

A few dump runs and the house is completely gone.

City hall has been ramping up its fee structure on everything lately, with the offsite levy really kicking in, the unfair way it calculates the asphalt degradation charges, and the surface improvement estimate. With the surface improvement estimate, the work is done at City rates, so there is no way to get the cost down. I find the surface improvements can be quite costly, especially when they try and get you for the streetlights as well. I never understood how a builder should pay for new streetlights that are on City property, and are used by the entire City. It isn't like a homeowner has a switch to shut off a streetlight near their bedroom window. Fortunately at the recent project there were no streetlights, so that could not be used as a way to increase the fee. The concrete cost is the largest I've seen to date on any of my projects. This is a byproduct of the lack of lane access so we need front driveways and new curbs. I guess we need to hope that the attached garage built form is attractive to the future owners so we can recoup the cost of the work.

It always hurts when these fees kick in before construction begins. These fees take a lot out of the budget that is needed to build the house, and the surface improvement wont be done until 2019. It would be far better if the surface improvement was paid for when it was built, not in advance. That is like financing City Hall operations for free for a year, and builder financing cost is far higher than City financing.

A few finishing touches and appliance adjustments and the first rowhouse residents are moving in. One townhouse unit remains available, will start to market it next week.

We started the rowhouse project in mid November and did some seriously difficult work in adverse conditions all winter. Occupancy was granted today, July 27th. That timeline suggests construction was around eight months. Occupancy is a huge relief. Once again finishing a project has proven to be really difficult with many hours invested.

The fences are up so that is a definite sign, I am ready to demolish a house and we can get building soon. This will be the sixth and seventh houses I will be constructing in 2018. That is a lot of construction and I’ve been super busy this year. The schedule has worked out fairly well as we are wrapping up the Threeplex and once that is done I will have time to focus on the new semi.

this house has only a few days left and it will be crumpled up in a dumpster.

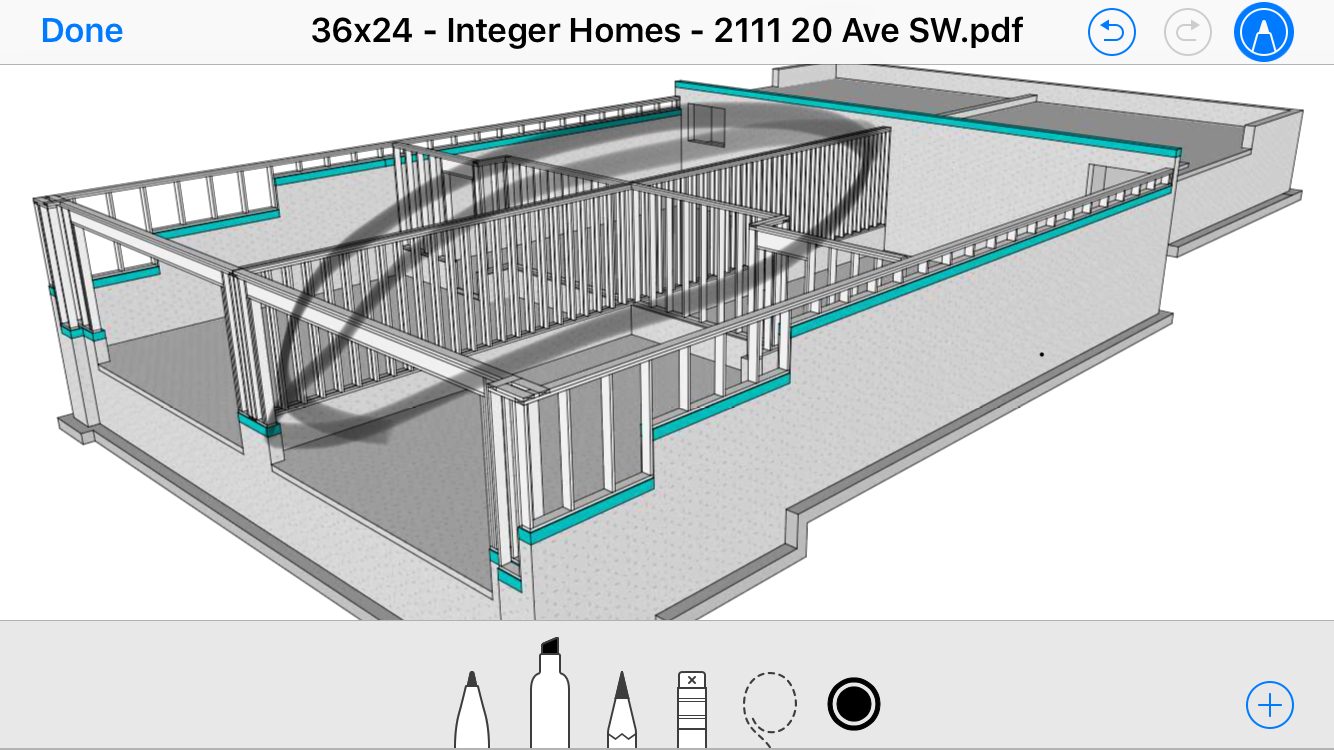

At the building permit stage the lumber yard supplying the structural components creates the truss and floor layouts. They do this on a proprietary software that produces considerable detail. I attempt to review each page in order to get a greater understanding of what I am commiting to buying and building. The renderings sure help a lot!

These are the roof layout rendering of my upcoming project. This is very appealing to me because I like simple roof lines that drain well and are predicable and easy to shingle. Most of all I want the roof cavity to have clear and obvious ventilate pathways that won't collect frost in the winter during a heavy snow year. This roof passes all of my criteria. What we have seen, especially last winter, is many roof failures from ice jammed valleys and snow blocked vents. Those are a nightmare to deal with.

More aluminum deck framing at the rowhouse project. At this stage this is really the last thing to do outside, with the exception of the garage door fiasco.

I will be calling what is known as the development completion inspection shortly. It is necessary to get this in order to receive an occupancy permit. I'm hopeful the city will overlook the lack of garage doors when this is done. I ordered custom garage doors that were going to be perfect for my project however the supplier sold them to another installer for an unknown reason. So my custom garage doors that I waited a month for were never even going to be arriving. Apparently the wait is four more weeks for new doors to be made.

This is a properly built deck frame. We've learned a lot about this product since the first deck started.

The live33st.com rowhouse is a large enough project that it seems able to absorb any amount of custom detailing. Instead of the usual tacked on house numbers I've elected to go with a custom fabrication and tested out a new supplier. Win win so far.

Nice font. Seems to really work with the background. I'd like to accept partial credit for the concept.

We are continuing the theme of material and technique experimentation at the rowhouse by incorporating a new deck system for the townhouse units. This is interesting because it likely will either be a total disaster, such as the material does not withstand the temperature fluctuations, or a huge success, and the material will prove to be durable and moisture free for many years. At this point I am still debating what is the more likely outcome.

after much screwing around and redoing screwed up work, the structure begins to come together. actually this is a photo of the original screwed up version of the frame.

And the newly fixed frame is almost 'decked out' in the new composite boards. looks good so far, but will it survive the harsh Calgary climate? We will find out soon...

UPDATE 2022 - the process is much improved thanks to the CICBA and the city improved its internal procedures, as has Atco gas. Goodbye and good riddance to the $4250 deposit fee!!!

UPDATE 2018 In an earlier post I described how awful it was to get a simple demolition permit from the City of Calgary. It required multiple trips to City Hall to essentially apply, pay a security deposit, re-apply, and finally get issued the permit. All of this took a lot of time, parking, driving, waiting in line, etc.

Much of this wasted time is now improved upon as the applicant can apply online, from anywhere, at any time. No more crowded waiting room lineups at the permit desk. All documents are uploaded through the vista/e-permit system, which is quite easy to navigate. The process still requires a trip downtown to pay the $4250 deposit, something that also should be changed as it needs a bank draft and a trip to the bank to get it, but the remainder of the process works well.

The key change they made other than online application, is the availability of the disconnect sheet. The disconnect sheet is the document that allows the collection of atco, enmax, and water department signatures. That remains a perilous and difficult process to get the signatures in a timely manner, but at least it can be done more easily. So the City initiative to remove red tape has finally brought me some efficiency benefits, what a relief!

And here it is, my first online demo permit app. What a tremendous improvement over the formerly archaic system. It is a real time and cost saving improvement at City Hall!

You'd think that inner city neighborhoods, some built around 75 years ago would be largely complete. In the case of Calgary youd be mistaken. Calgary loves to tear out the old stuff and replace it. Most of the lanes in these older areas were never even paved. Decades later this lack of asphalt has become a real pain. Now we have multiple trash bins and more density every year. Along with the new houses comes higher expectations. Those individuals paying an average of $6k per year in property tax tend to want the city to provide services.

Paved lanes isn't a service the city offers unless the residents offer to pay for it via a vote. The lane between 34 and 33 st which happens to be my block is currently being paved. After the snow and hideous cold winter we suffered through where our lane became impassible for weeks at a time, paving will be a welcome relief.

Unfortunately some of the newer houses (and older ones too) were poorly designed and the grades don't work with the new lane. This could be a major garage access problem. Grades are a tricky issue and often I struggle with blending in the old and new grades. I didn't dig my own garage as low as it optimally could be and this is truly aggravating. But compared to my northern neighbour mine is at least serviceable.

This is what happens when the grades aren't considered at the time of construction.

After many hard months of building it is always a relief to see the landscaping work nearing completion. Laying sod and planting some trees makes a big difference on a corner site in particular. The rest of the month will be a push to get it all wrapped up in time for the clients to move in. So far we appear to be on schedule and possibly even a little ahead on the first townhouse.

Sprinklers, loam, sod, mulch, trees.

And water is hooked up so sprinkler system can function. Much tuning still required but the sod will survive the July heat.

Rowhouse work continues this stampede weekend with more floor install and the finishers lockout in the first house. Baseboards, door hanging, door hardware and closet rods are some of the lockout tasks. Next up it is time to get the decks done and the garage doors hung, plus begin the final inspections.

Not particularly photogenic work underway inside the rowhouse. More to come next week.

The landscapers are on day 2 of the rowhouse project. Fill was added in some areas to reach closer to final grade and the fence posts drilled and grouted in place. The irrigation contractor has also installed the network of pipe and nozzles for sprinklers. Having a programmable sprinkler is a real time saving luxury item. Without sprinklers keeping the various patches of sod and trees watered is difficult. Note we had to leave a lot of conduit under the sidewalks to allow passage of the water pipe. Without that install is a big problem.

Ready for loam and sod

Foundation planning can be a challenge particularly with custom homes on unique sites. I'm working with a design company now on my new semi detached product. Built into an upslope with an attached garage and courtyard style back yard there is a lot of grade work to manage.

Many small details to resolve

With final installation of finishing material underway at the rowhouse project we are continuing to overcome obstacles to completion. The basement slab insulation was not nicely detailed with the top of foundation wall. This led to some awkward interface issues and uneven concrete to cover with flooring.

Nasty area to cover with flooring.

Self levelling compound applied

And flooring can be completed

My metal cladding crew is scheduled to begin work just after the long weekend. This is good news as we can then finish the entire garage and finalize the building exterior. What won’t work is the combination of screw they supplied along with my costly fire detailing on the garage. For whatever reason the City requested fire proof walls be built in the garage. This led to the garage walls being layered with 1 1/4 inch of type x drywall inside and out. I bought $200 worth of expensive drywall self tapping screws but the siding guys are going to have to get more creative.

not a lot of grip here.

We are wrapping up our adventure in interesting feature wall tile. The finishing material selection and install is definitely the most fun part of the project. I need more finishing and less starting of construction projects. Here are a few shots of the interesting tile selections